Hydro Trike

At Vervaet, we believe in the added value of quality and the power of simplicity. Why? Because our products originate in our contracting firm and we listen to the feedback and requirements of our customers. Together with our innovative character – we invest almost 10% of our turnover in research and development (R&D) – we develop the best-performing and most profitable machines on the market for you.

A professional self-propelled manure processor is nothing without a professional driver who can work comfortably for hours on end, if need be, without becoming too tired. That’s why all Vervaet self-propelled machines, including the Hydro Trike, are furnished with the most modern, luxurious and spacious cabs with a large area of glass. The controls for the entire machine are within easy reach: the gear lever and the terminal are located in the adjustable armrest.

'This Hydro Trike XL is our fourth Vervaet machine. We never have any doubts when purchasing a self-propelled machine. Because of its simplicity, the Hydro Trike is indestructible and easy to operate. Combined with Vervaet's service, we are and remain convinced.'

Jan en Tom van Alphen

Owners of Van Alphen contracting firm and biogas plant (NL)

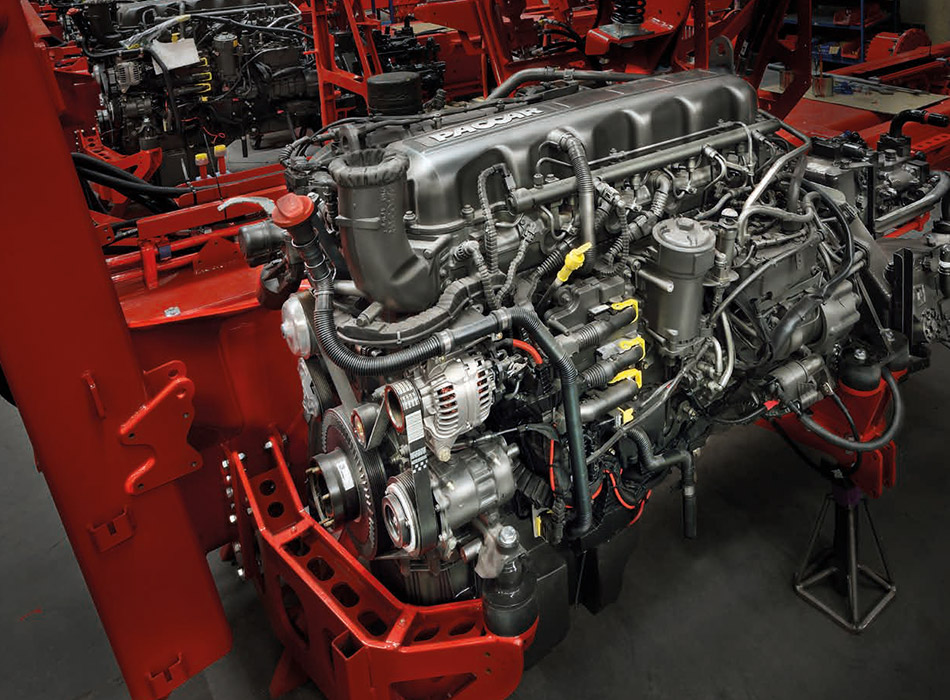

Reliability is what counts when a lot of work must be done in a short amount of time. This applies in particular to manure application. That's why Vervaet opts for reliable quality components and parts, such as DAF PACCAR diesel engines. In the Hydro Trike, this is a 530 hp six-cylinder diesel engine which delivers its maximum capacity and torque at less than 1,400 t/min. Often, 1,250 t/min are enough to be able to get the job done.

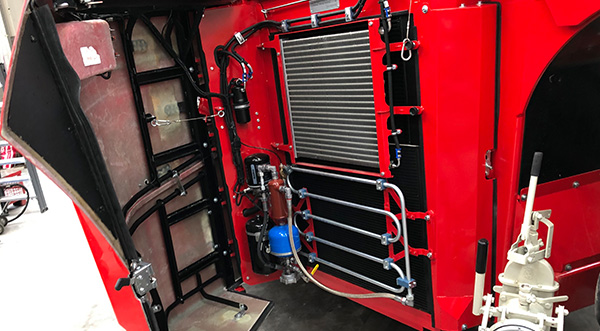

Vervaet is also committed to quality in terms of hydraulics, offering two adjustable Sauer-Danfoss pumps for the hydraulic drive. The rear axle drive is a combination of a large hydraulic engine with a mechanical cardan shaft for optimal traction. The manure pump is hydraulically driven, making it precisely adjustable.

The Hydro Trike 5x5 comes into its own when working on hilly and undulating terrain, further extending the machine’s capabilities. With the 5x5 fertilizer application is now possible on hillsides, where all-wheel drive is the all-important solution, according to customers.

Drive to the mid-wheels is provided by a self-contained system with a 175-litre-per-minute hydraulic pump capable of providing an impressive 130hp. A new three-point suspension system replaces leaf springs with repositioned shock absorbers at the front of the axle. An inclination sensor, which detects whether the machine is on a side-hill, allows the system to automatically lock the suspension on the far side.

An example of the innovative strength of Vervaet and its partners is Vervaet's 2016 world exclusive – a fertilising machine which dispenses the right nutrients in precisely the right location. Fertilising in cubic metres per hectare has been replaced by kilograms of nitrogen or phosphate per hectare, in a location-specific manner. This is possible thanks to the near-infrared (NIR) sensor which varies manure delivery based on the composition of the slurry. Fully automated – you don't have to do a thing!

And via the Vervaet Smartbox, you can connect virtually any GPS system to the Hydro Trike's Isobus compatible section switch for ultimate flexibility. This prevents overlap and helps your customers remain inside the spreading area.

Filling the tank of the Hydro Trike may be a necessary evil, but our designers have done everything they could to make that process as quick and efficient as possible. The standard suction arm has a diameter of 8" and extracts manure from a manure container just as easily as from a deep manure cellar. Optionally, this suction arm can be 10" in diameter.

For a fertilising machine, nothing is as important as manure transport. A continuous cycle of extracting, cutting, pressing, pumping and applying – often 24 hours a day. At Vervaet, you can rely on a tried and tested, reliable manure system that has its roots back in 1990. This includes the cyclone cutting mechanism developed in collaboration with contract workers and which offers capacity, simplicity and ease of use.

Because the cyclone cutting mechanism is located behind the manure pump, there is minimal resistance on the suction side of the manure pump. The manure pump continues operating during manure spreading, switching to circulation on the headland, with the fertilising unit raised. During circulation, the cutting device is continually cleaned to prevent blockages. As a result of circulation, manure reaches the crops and soil on time when the fertilising unit is lowered.

When you invest in the Hydro Trike, you not only receive its performance. You will also receive a team focusing on keeping your fertilising machine running. Professionally trained engineers know every detail of your machine and can quickly address any problem. Because of the machine's standard diagnostics system, 95% of the problems can be solved by telephone. This saves both you and us a lot of time and money.