Beet Eater EVO

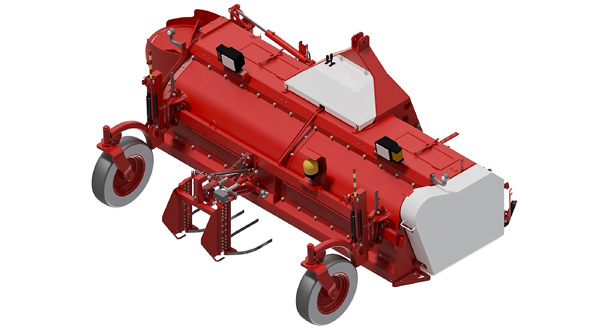

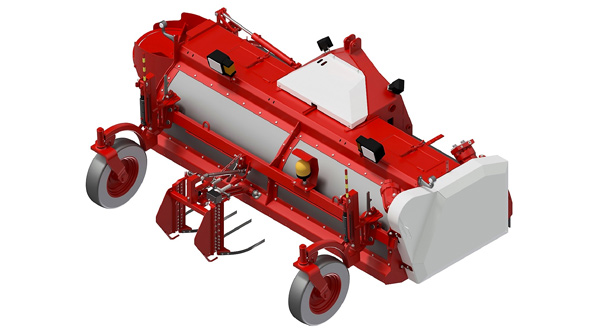

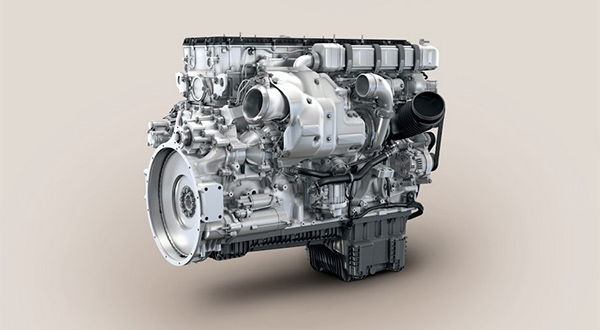

If you invest in a Vervaet beet harvester, you invest in quality – a quality which is expressed in the components and parts used as well as the final product. With the experience we have gained since 1974, you can be sure that we know all the strengths and weaknesses of our products and that we are continuously improving them. You'll also find that our machines are not unnecessarily complex and won't require a great deal of maintenance. Our machines are well thought out and cleverly designed so you can continuously harvest throughout the season, problem-free and without major maintenance. And if there is a problem, we can solve it remotely in 95% of the cases.

A professional harvesting machine is nothing without a professional driver who can work comfortably for hours on end, if need be, without becoming too tired. That’s why all Vervaet self-propelled machines, including the Beet Eater EVO, are furnished with the most modern, luxurious and spacious cabs with a large area of glass. The optimum position of the cab means that the driver has an exceptional view of the topping and lifting work. The controls for the entire machine are within easy reach: the gear lever and the terminal are located in the adjustable armrest.

When it comes to harvesting beet and chicory, the Bartels Group in Moerstraten (in the North Brabant region of the Netherlands) has been loyal to Vervaet since 1986. Why? Because service makes the difference! That’s what Vervaet driver Peter Pellis says and, after 40 years in the job and 10,000 harvested hectares since 1986, he knows what he’s talking about:

'We've been harvesting sugar beet at Bartels since 1982. Back then, we used a two-row Stoll harvester. We acquired a used six-row machine as long ago as 1986 – a Vervaet Heyens that lifted 80 ha. That was also my introduction to the Vervaet family and their reliable equipment and service.

Despite the fact that Vervaet’s prices were sometimes higher than the competition, we always went for the excellent service, high resale value and the outstanding quality. Quality costs money.

We started, and continued, driving Vervaet machines because of the good service and the willingness to deal with any problems. Our customers chose and continue to choose us because of how well we lift chicory and sugar beet.'

Peter Pellis

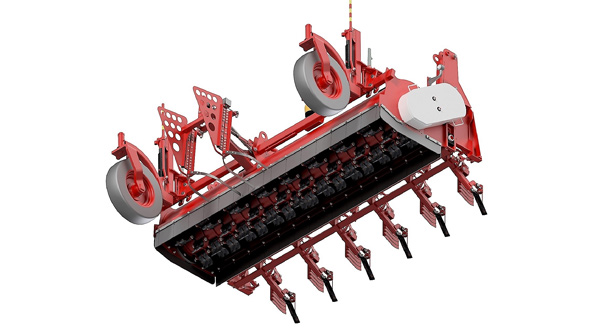

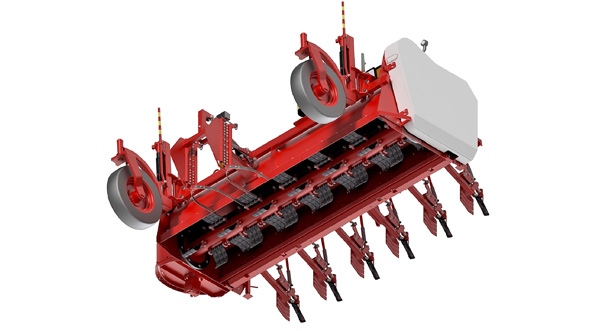

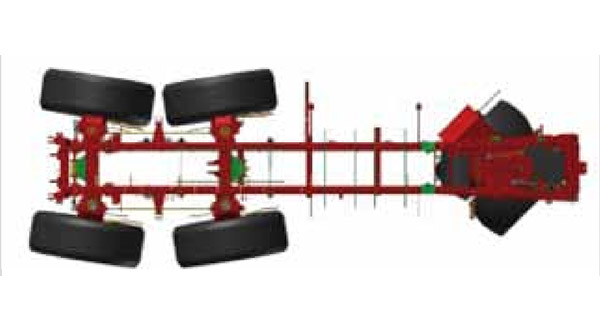

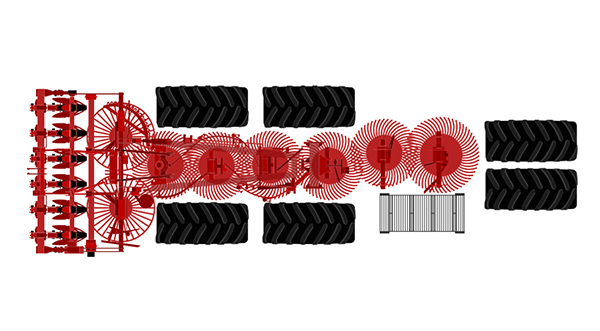

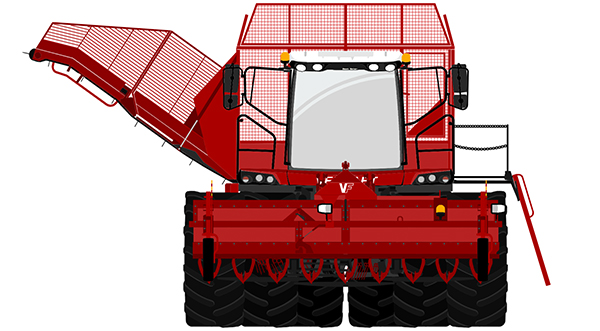

The next step up in capacity is the nine-row Beet Eater 925. This machine is identical to the Beet Eater 625 except for the nine-row lifting unit and the telescopic front axle. To guarantee optimal harvesting in the connecting rows, the lifting unit is equipped with depth control for every three rows. The space created behind the lifting unit is used to extend the two front wheels, to at least 4.5 m, for better support and a more even ground pressure. An extra advantage of the telescopic front axle is the ability to continue with the harvest in even the most difficult of circumstances.

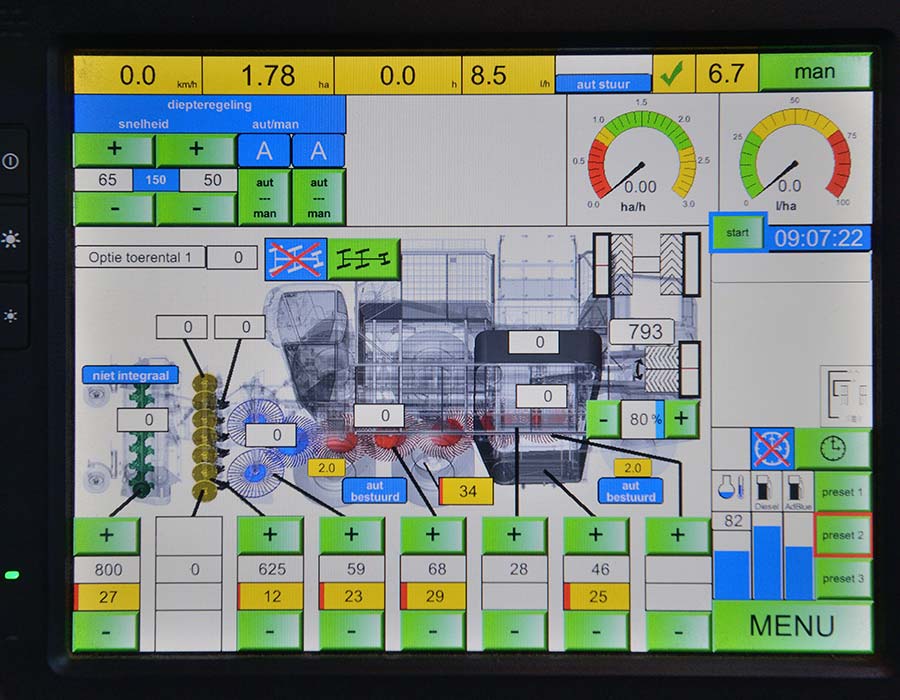

With the multifunctional 26.5 cm touch screen, the driver has all the required information on a single, conveniently arranged full-colour screen.

Moreover, all necessary settings can be easily changed in the menu.

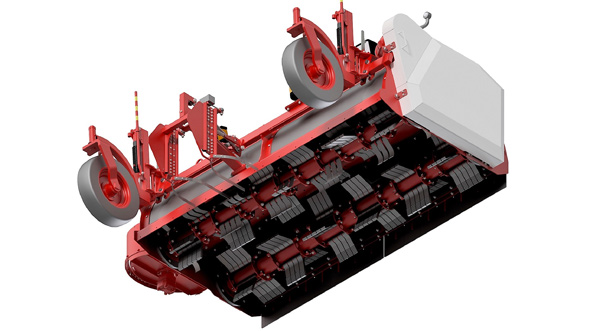

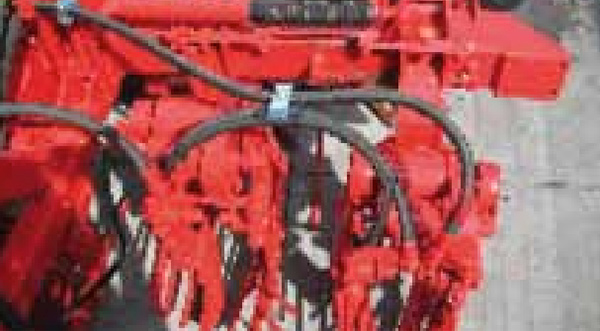

The entire Vervaet Beet Eater has been built in view of the highest possible quality with minimum required maintenance.

The direct Vervaet Service Team of professional factory engineers and rapid delivery of parts offers you, as a customer, the security that the Vervaet Package is the most trustworthy and reliable machine combination.