Q-Series

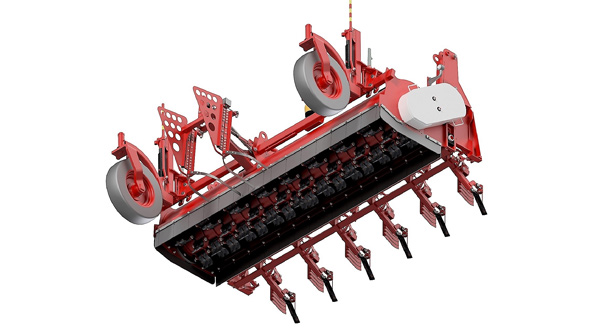

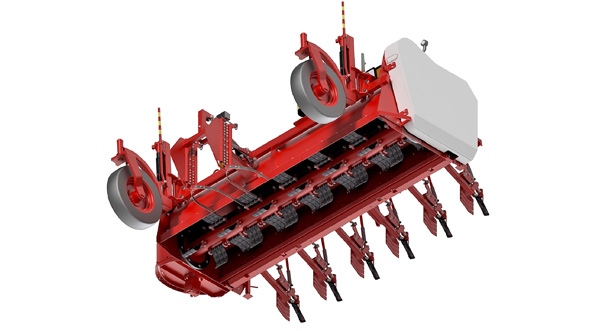

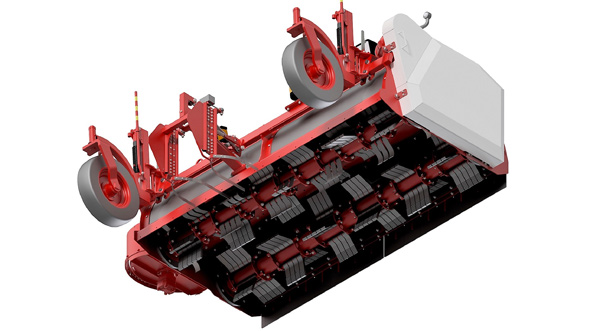

The Vervaet Q series is the iconic manoeuvrable, lightweight and modular capacity harvester which keeps going where other harvesters must stop. How is this possible? Because of its low weight with only one wheel per track, resulting in even ground pressure, and its numerous cleaning systems. These features make the Q series the perfect self-propelled beet harvester for crop farmers and contract workers alike.

A professional harvesting machine is nothing without a professional driver who can work comfortably for hours on end, if need be, without becoming too tired. That’s why all Vervaet self-propelled machines, including the Q-serie, are furnished with the most modern, luxurious and spacious cabs with a large area of glass. The optimum position of the cab means that the driver has an exceptional view of the topping and lifting work. The controls for the entire machine are within easy reach: the gear lever and the terminal are located in the adjustable armrest.

If you want to harvest beets, chicory or celeriac on the slopes of ditches or in hilly conditions, opt for the Q level master in the Q series for fully automatic levelling of the machine. This unique technology keeps the superstructure of the harvester level as circumstances demand, in hilly conditions, for example, but also on the (descending) slopes of ditches. The hydraulic levelling provides extra stability and the pressure on the ground is spread more evenly.

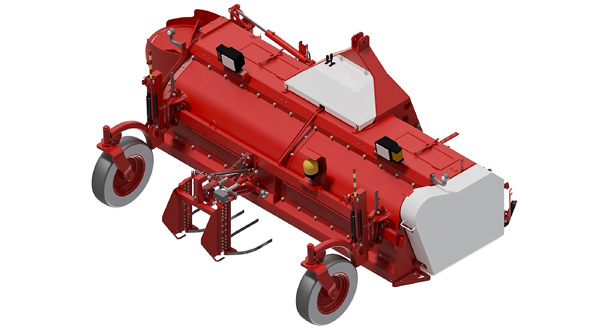

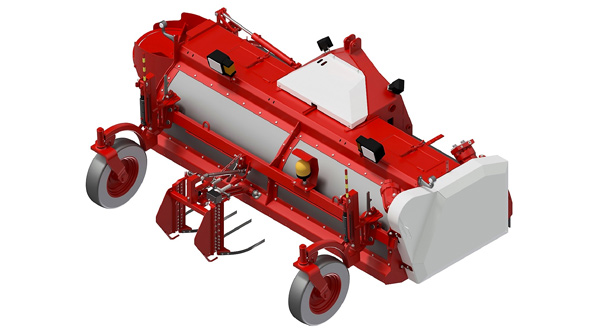

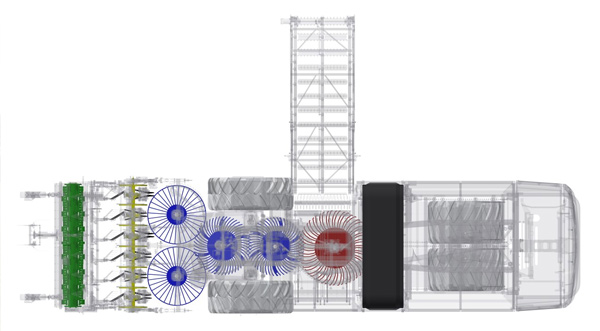

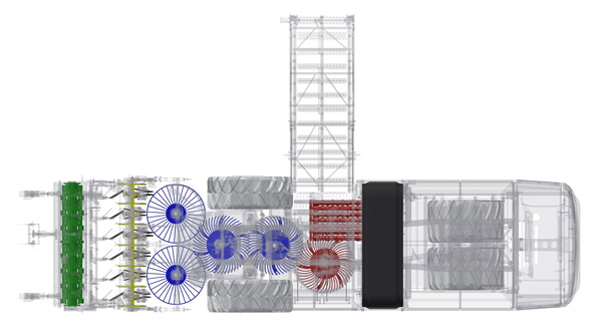

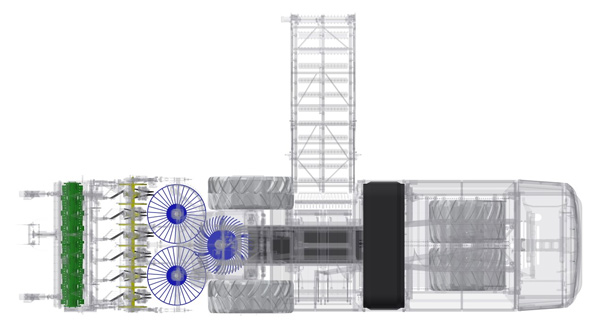

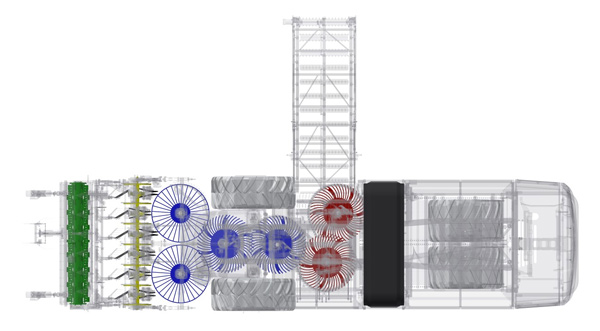

The Q series is so compact and manoeuvrable that it can virtually turn on its own axis. With an internal turning radius of only 1.6 m, turning on the headland was never this easy, quick and soil-friendly. The two rear wheels are mounted next to each other on a turntable. Moreover, the front wheels have a steering wheel movement of 8 degrees, which results in practical and supreme manoeuvrability. All wheels are controlled by the automatic steering controls.

The arrangement of the two rear wheels between the front wheels evenly distributes the weight across the width of the machine.

The entire Vervaet Q series has been built in view of the highest possible quality with minimum required maintenance.

The direct Vervaet Service Team of professional factory engineers and rapid delivery of parts offers you, as a customer, the security that the Vervaet Package is the most trustworthy and reliable machine combination.

The engine is easily accessible for daily checks of oil, water and the air filter. Steps have been installed for convenience and safety. The machines have a standard compressor and connection at the rear of the machine to blow clean the radiator or pump up the tyres.